Taming a cool steam vent seems like a good idea at first, free water and power. However many players quickly learn that taming a cool steam vent is more difficult than it first appears. The steam is too cold to be used for a steam turbine, and heating up the steam is more trouble than it’s worth.

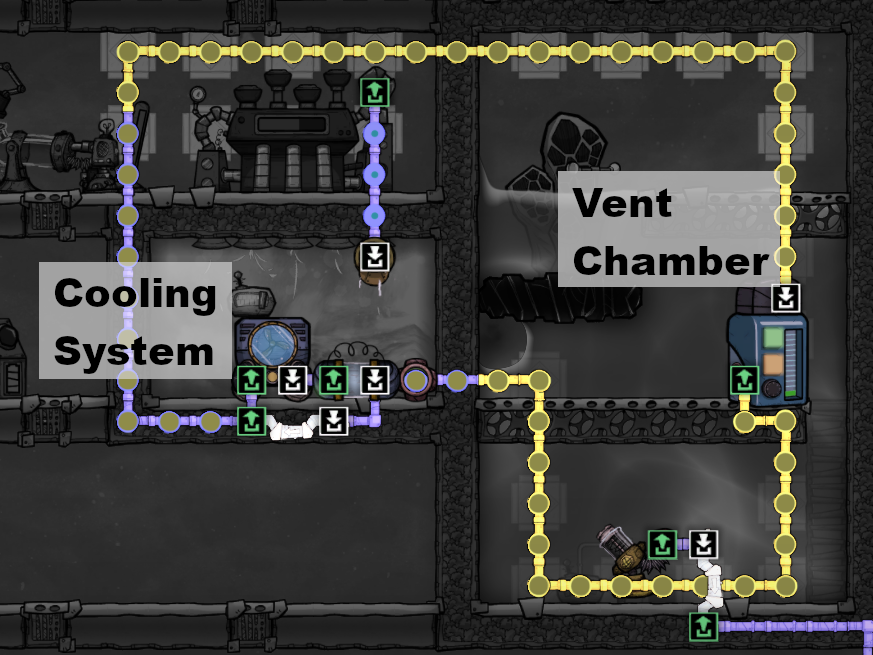

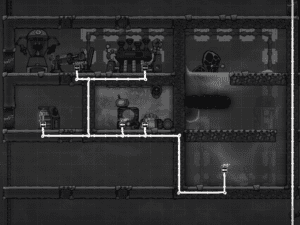

This guide utilizes a closed-loop cooling system. The purpose of this system is to effectively cool down the steam vent chamber. The process involves condensing the steam into water and subsequently cooling the water to achieve the desired temperature before it is pumped out.

Setup

Make sure you have researched steam turbines, thermal aquatuners, and basic automation. If you haven’t unlocked this tech, then wall off the steam vent to prevent the base from over heating until you are ready. Steel and ceramic are recommended for this build as the steam chambers get hot and can break things.

The cooling system uses polluted water, which is available early game, has a low freezing point of -20°C (-4°F) and high boiling point of 119°C (390°F). These temperatures work well with the steam and liquid water. The polluted water won’t turn to steam due to vent heating, and is resistant to freezing at lower temperatures.

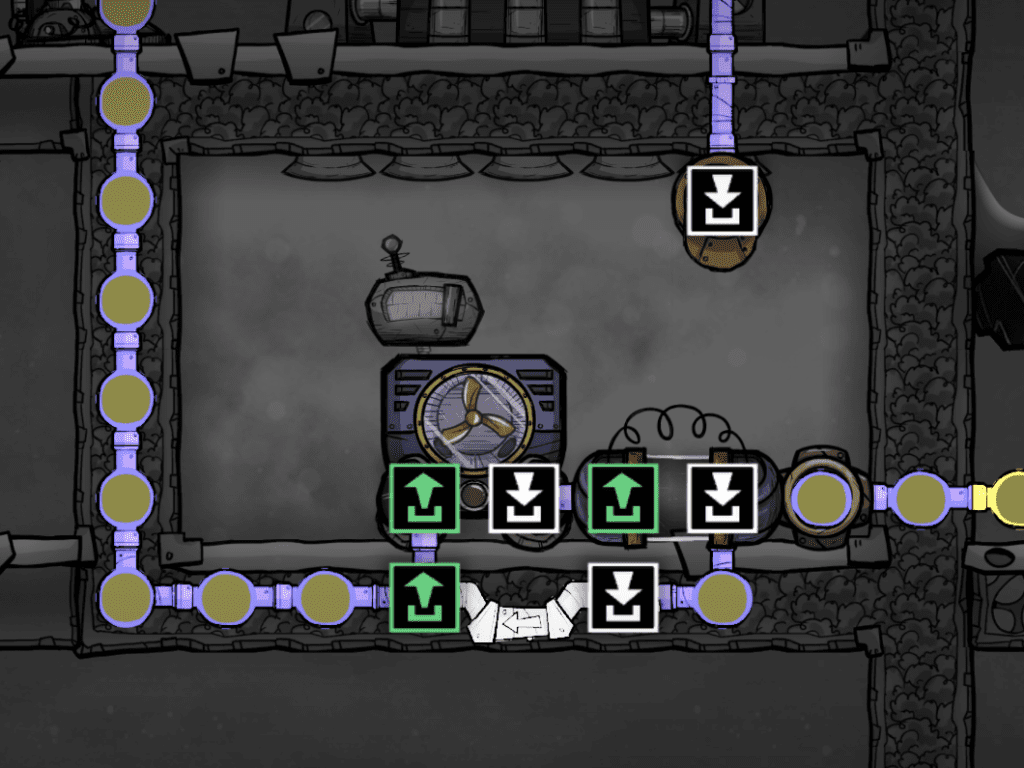

The cooling loop is a thermal aquatuner in a steam chamber cooling system. As the polluted water passes through aquatuner the heat is displaced into a cooling system room. The cooling system room powers the steam turbine, which coverts some of the heat back into power. These pipes are insulated ceramic pipes.

The cooled polluted water then moves around loop, where it cools the power generators and the steam vent. These are radiant gold pipes. In the vent chamber, the steam will condense into water and collect at the bottom. At the bottom of the vent chamber connect a thermo sensor to a water pump, set to send a green signal if below 25°C (77°F) or the temperature you would like out.

Cooling System

The polluted water is cooled by the aquatuner. Connect the aquatuner to a thermo sensor, that sends a green signal if below 200°C (392°F). If the steam gets too hot, the thermo sensor will disable the aquatuner before it breaks and allows the steam to cool it.

To prevent the polluted water from freezing in the pipes there is a liquid pipe thermo sensor with liquid shutoff. The liquid pipe thermo sensor is set to 0°C (32°F), at which point it will close off and polluted water will by pass the aqua tuner. If you need more help with the bypass setup see our How to use a pipe thermo sensor, guide to sorting hot and cold liquids (and gases).

A hydrogen or coal generator will also be needed to power the aquatuner. The power generator, steam generator, aquatuner, pump and shut off can all be on the same power line when using conductive wire. One hydrogen or natural gas generator will be enough in a power plant room. A coal generator will not provide enough power until the steam generator starts up, in many cases you may need two coal generators.

Hot cold cycle

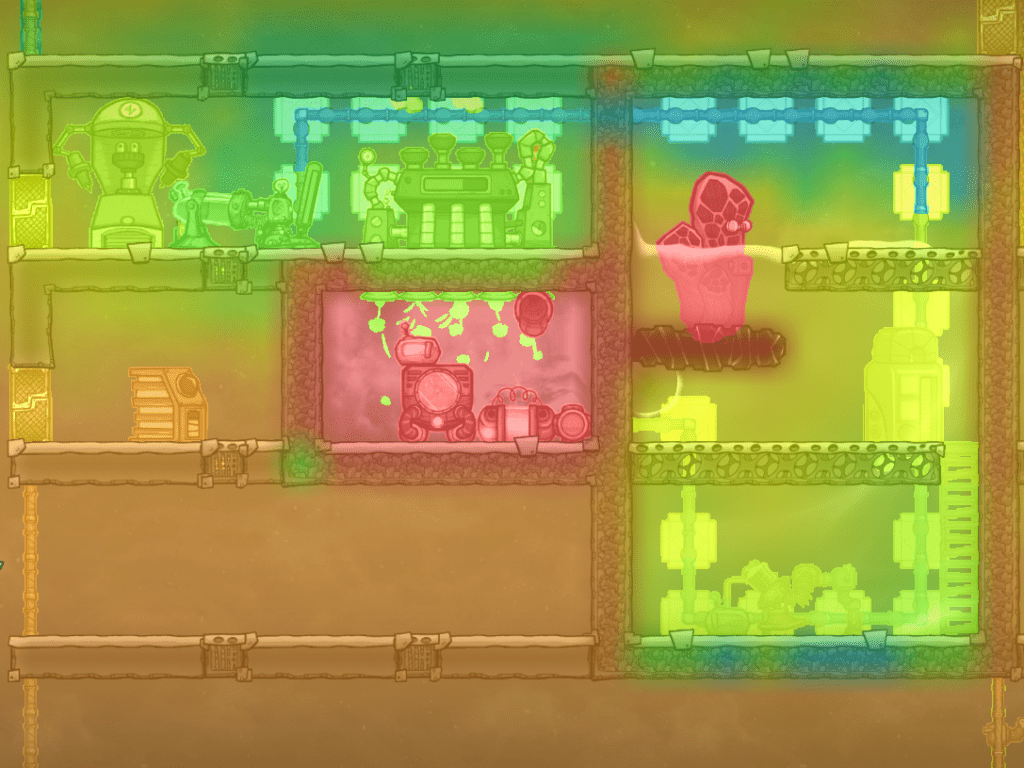

The area will go between a hot active vent phase and a cold inactive vent phase. If your base is usually within normal temperatures, then the steam engine will sit at around 45°C (113°F), if it’s a bit hotter it may need a wheezewart to keep temperatures more comfortable for dups.

Temp shift planes can be used around the radiant pipes to help temperature spread out.

Tips

Starting the system can be tricky, with the steam chamber you can pump some water in or build some ice temp-shift plates (which will melt). Then it’s a matter of time until it turns to steam. You’ll need the steam to push any oxygen out of the steam chamber before closing it off. If a layer of oxygen gets trapped between the steam and turbine the system will overheat and break.

This setup can also be used for salt water geysers.

Tempshift plates behind the power generators helps to prevent too much heat building up in the area. Make sure you have two rows spaced out behind the steam generator.